Design and development to Debottlenecking – made simple

Reactor Design now hits Main Street - away from the grip of experts alone. It can be done now by process engineers and can be treated as another unit operation in their plant design and optimization.

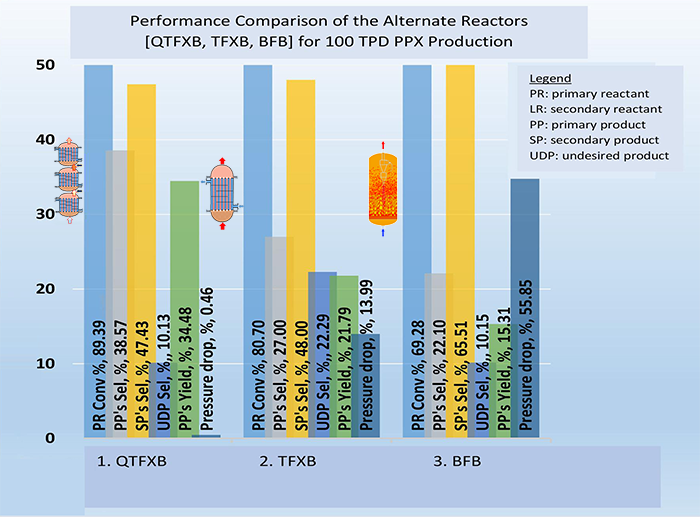

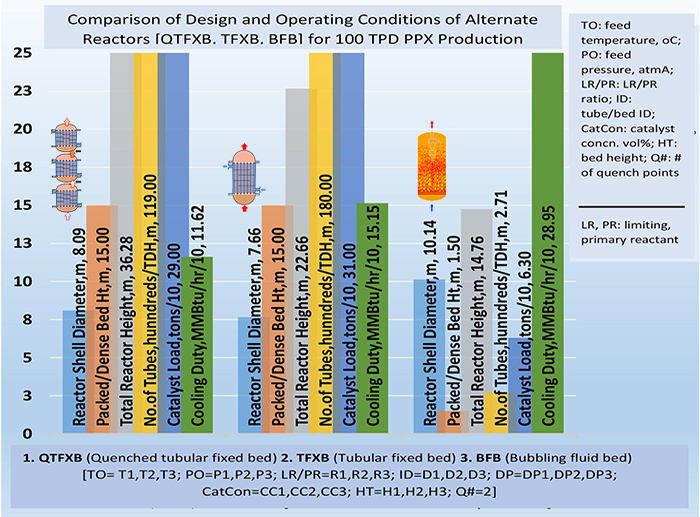

- Use one or more from a line of road-tested ready-to-use reactor modules that integrate built-in hydrodynamics, flow characteristics, fluid-solid interactions and heat, mass and phase transfer phenomena with process chemistry/ mechanism and kinetics to provide you the performance of each reactor type and operating mode.

- It utilizes built-in thermo-physical and transports property databases to carry out the integrated model execution for each reactor module.

- Models are built on fundamental principles of reaction engineering, and phenomenological and hydrodynamic behaviors of each reactor and avoiding empiricism to the extent possible.

- Definition and 14-steps details of ‘how-to’ build a robust reactor model are provided in a

CEP cover-page publication

authored by a member of Difrex team.

Follow a simple

3-step process

to design the selected reactor

or alternate reactors – promptly.

Complete

design and

performance details appear

instantly on the

Work Page

in pop-up plots and tables upon model execution. Use a similar process for development and debottlenecking.

Zoom in!

....you should find all you need

- You have reached the Decision Gate with the preliminary design

- Now, follow recommended steps toward testing, pilot/ demo campaigns (as necessary) to complete the final and detailed design with auxiliary systems, safety shields, emissions controls and reactor operation and control system design or call Difrex

An entrepreneur, engineer or chemist should find the Difrex model packages useful for innovative catalyst and process developments and monetize new idea or chemistry. The complete package (the gold GRM™-x) can be helpful in a variety of tasks carried out routinely by a corporate R&D team for environment, energy, coal, biomass, chemicals, petrochemicals and minerals plants and projects.