A reactor or reaction system has not been treated as another unit operation in a process plant – like a separator, settler, heat exchanger or a compressor. It is usually treated as a black box where all upstream operations feed into and downstream operations begin. Rest of the plant design with all unit operations are geared to meet the needs of the feed and narrow feed/ operating conditions and to treat the effluents according to original design of the reactor. Reasons include protections of trade secret and control by reactor vendors, and presumed risk and fear.

But reactor is the heart of the plant. And it is a black box –

no more.

Its design and development to Debottlenecking are now made

simple

.

Unlock the full potentials of your plant now

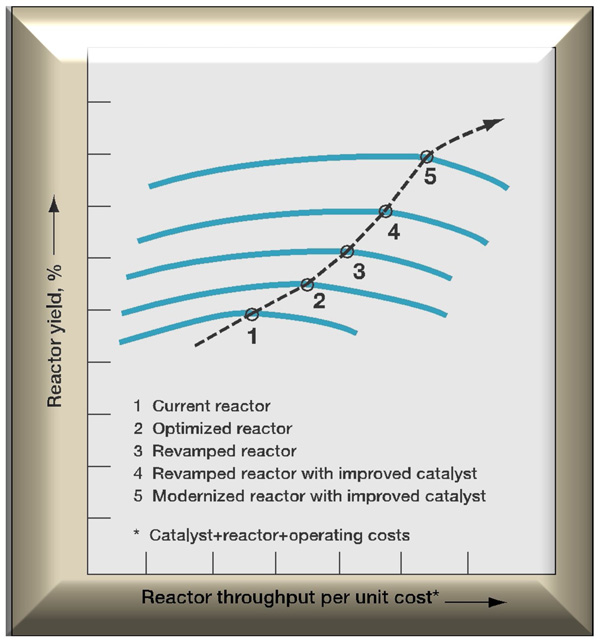

Although original CAPCOST of a reactor may be only 10-30% of total plant CAPCOST a substantial saving in OPCOST of the up- and downstream processing units by the new and true or full plant optimization process may lead to substantially improved profit from the operating plant

Now you can* also carry out revamps and upgrades of most reactors as you need and almost as easily as another unit of your plant with or without Difrex help

*Barring legal constraints