Auxiliaries, details, start-up/ shut down, operation/ control, emergencies, BED....

Although many final details beyond the key design specs and operating

conditions are to be filled in by process engineers, there are aspects that still fall under the

primary responsibility of the reactor designer. These aspects are usually not addressed by most

computer models. Ignoring these aspects, inadequate or wrong solutions to

these issues

may lead not only to project failure but also to disastrous consequences later in a running plant

These include reactor

safety:

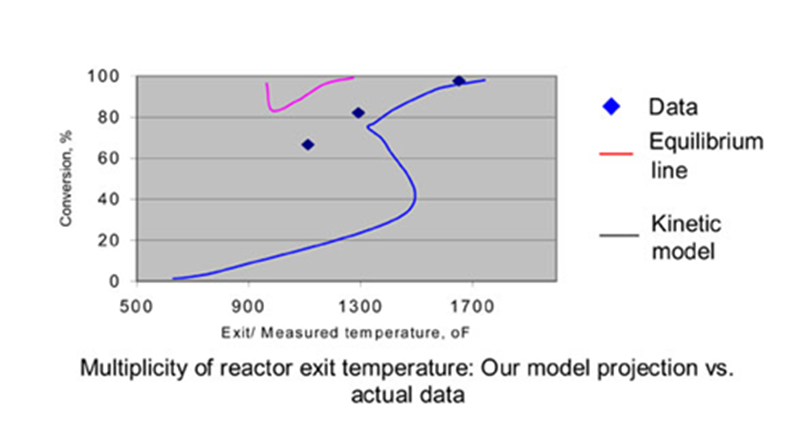

It’s not just addressing reactor instability that may cause temperature runaway, but also

potential Deflagration and detonation that may lead to the most disastrous consequences in

a running plant

Also included are

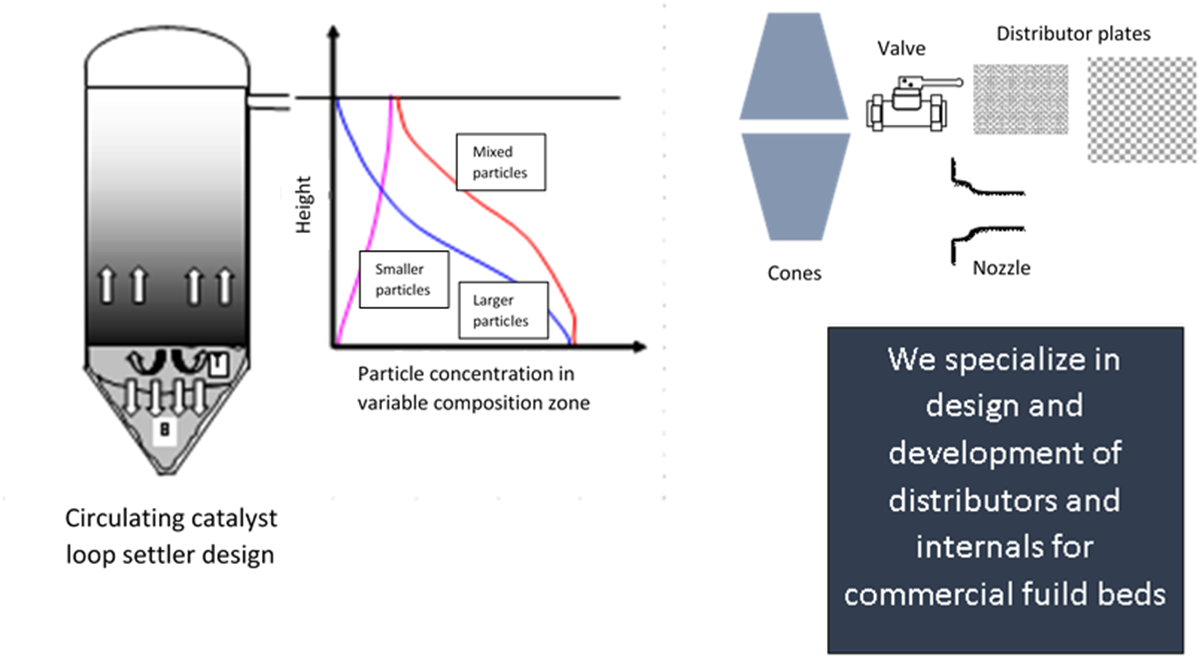

- Inlet/ exit nozzles, cone/ dome designs

- Fluid/ solids distributor designs

- Multi-stage feed injections when necessary

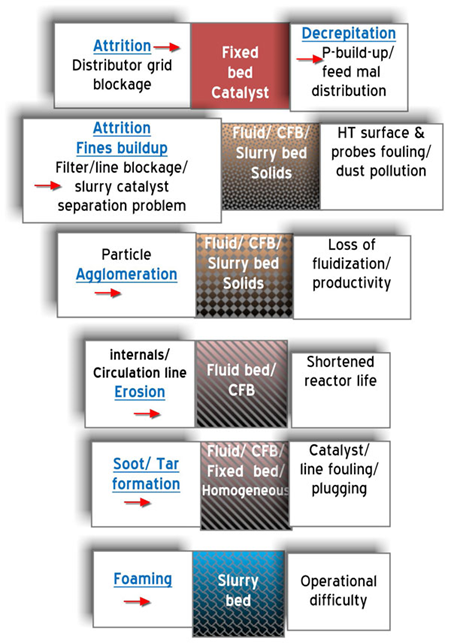

- Potential foaming problem

- Fines build-up

- Line/ distributor depositions, plugging

- Selection of particle size and shape in packed beds

- Stagnant zones/ hot spots

- Assuring packing uniformity

- Catalyst/ particle lumping/ agglomeration

- Soot formation

- Internals/ cooling coils fouling/ coking/ erosion

- Cooling coil/ bank layout, detailed design

- Catalyst fouling/ coking/ attrition

- Lines/ bends erosion

- Pneumatic/ circulation line choking/ blockage

- Fluid-solid circulation lines for adequate capacity

- Reactor-Regenerator (dual bed system) coupling - on-off line/ batch or

continuous

- Pneumatic/ circulation line, bend designs

- Cyclones - internal or external?

- Cooling – internal or external?

- Catalyst separation/ filter/ settler/ circulation loop

- Circulation loop pressure balance

- Return lines/ dip leg/ aeration ports designs

- Sensors/ probes orientation, distribution and locations

- Temperature/ pressure set points and controls

- Emergency/ blanketing measures

- Start-up and shut-down procedures

- BED package

We perform gap analysis to prioritize the areas according to the effort

needed for a specific job at hand. We do what-if analysis to determine what may go wrong

after a reactor is in operation, and its safety and emissions. We do so-what analysis to

establish the process economics